SMOOTH

- Standard hydromat collet

Click on the product image to get 360° view

SAW BURR CUT

- Improved runout, as sawing burr can be reliably picked up in the clearance area

Click on the product image to get 360° view

SQUARE

- Suitable for square material

Click on the product image to get 360° view

HEXAGON

- Suitable for hexagon material

Click on the product image to get 360° view

SPECIAL PROFILES

- Various profiles possible

- Profiles can be adapted individually to the workpiece

Click on the product image to get 360° view

SPECIAL CONTOURS

- Complex contours can be realized by hard milling, hard turning and grinding

- Already possible with smallest diameters from 0.2 mm

Click on the product image to get 360° view

S-SLOT

- High and constant clamping force

- Clamping with virtually no clamping marks

- Alternatively usable for profile material (corner clamping)

- Prevents the entry of machining chips, as the collet closes almost completely

- Easy to clean after use

Click on the product image to get 360° view

L-SLOT

- High and constant clamping force

- Clamping with virtually no clamping marks

- Alternatively usable for profile material (corner clamping)

- Prevents the entry of machining chips, as the collet closes almost completely

- Easy to clean after use

- Ideal for clamping short clamping surfaces

Click on the product image to get 360° view

W-SLOT

- High and constant clamping force

- Clamping with virtually no clamping marks

- Alternatively usable for profile material (corner clamping)

- Prevents the entry of machining chips, as the collet closes almost completely

- Easy to clean after use

Click on the product image to get 360° view

Z-SLOT

- High and constant clamping force

- Clamping with virtually no clamping marks

- Alternatively usable for profile material (corner clamping)

- Prevents the entry of machining chips, as the collet closes almost completely

- Easy to clean after use

Click on the product image to get 360° view

THIN SLOTTED

- Clamping with virtually no clamping marks

- Prevents the entry of machining chips, as the collet closes almost completely

- Recommended for small bore sizes

Click on the product image to get 360° view

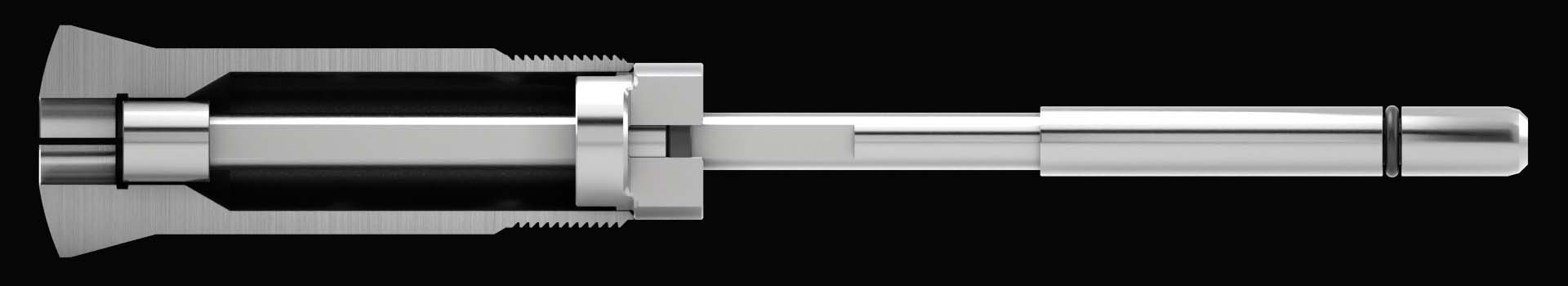

QUICK CHANGE VERSION

- The quick change version is screwed into the collet sleeve and locks itself automatically

Click on the product image to get 360° view

EJECTOR BAR / EJECTOR SLEEVES / STOP HEADS

- Are part of a module for hydromat collets to eject or stop workpieces

Click on the product image to get 360° view

HYDROMAT REDUCING SLEEVES

- Are inserted in Hydromat collets, this allows to clamp two different diameters with one collet

Click on the product image to get 360° view