WELCOME TO SCHLENKER

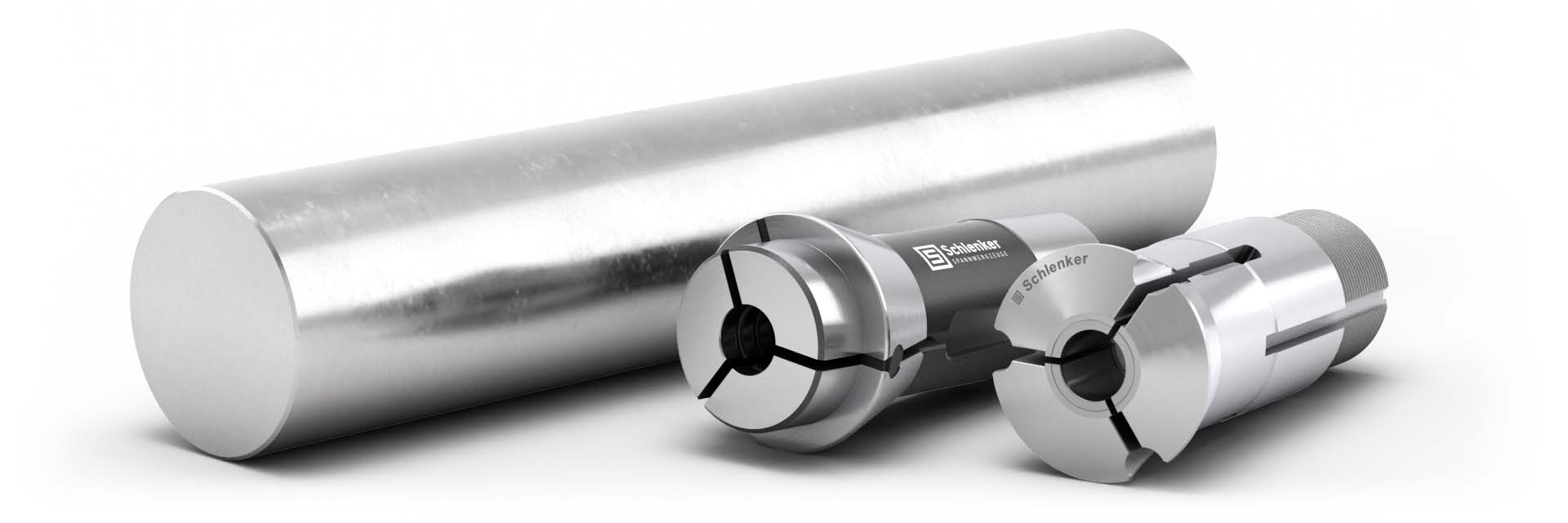

Since its foundation in 1952 by Hans Schlenker, the Schlenker company has fully specialized in the production of high-quality clamping tools.

“Think different, create innovations”

Always on the leading edge to give you added value.

THE COMPANY

SINCE 1952

For more than 70 years Schlenker Spannwerkzeuge GmbH & Co. KG dedicates all its passion and knowhow to the production of high-quality clamping tools.

In the beginning the company focused on the manufacturing of collets for manual as well as CNC lathes. When Dipl. Ing. Josef Meißner took over the company in 1986, he developed the first bar feed collet for loading lathes in close cooperation with loading magazine manufacturers. After the first sliding headstock lathes came to the market, the company expanded its product portfolio with guide bushes. These products are still essential for the company today.

Unimpressed by the first relocations of production by German companies abroad, Schlenker always stayed true to its roots and continued to produce at its home location in Villingen-Schwenningen.

Britta Hoffmann continues this tradition since 2008 as Managing Director in the second generation. The family-owned company is highly regarded by the market as a technological leader for clamping tools and is continuously expanding its business with customer-specific and innovative product solutions.

This success is driven by the company’s more than 100 highly qualified and passionate employees, who form the heart of Schlenker.

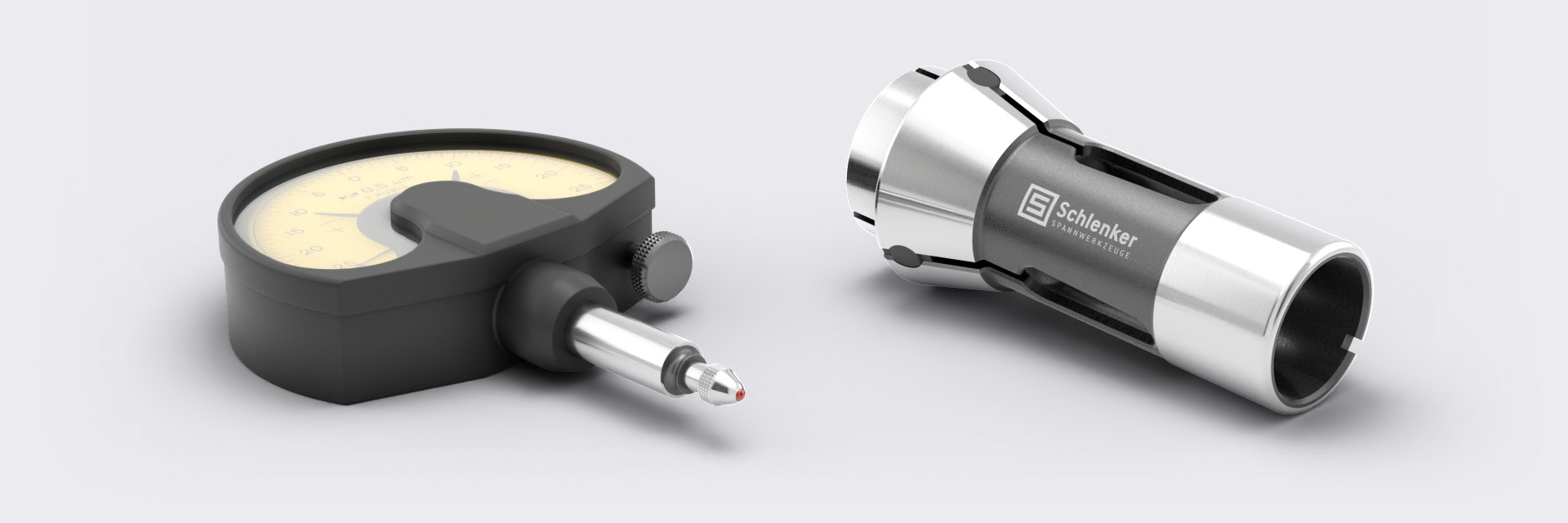

SCHLENKER QUALITY

OUR CLAIM KNOWS NO COMPROMISES!

Quality is inseparable from our corporate success, thus we relentlessly focus on Germany as a production location.

From standard to specialized product solutions with options that provide our customers with decisive added value. Optimized production processes allow us to provide special and custom made solutions with about the same lead time as standard products.

SCHLENKER PRODUCTION

WE PRODUCE EVERYTHING 100% OURSELVES!

In order to ensure the highest quality in the long term, we leave nothing to chance and work with a high level of added value. That’s why we combine all production steps carried out by highly experienced specialists in-house: turning, hardening, grinding and eroding – everything from a single source.

This set up makes us extremely fast and flexible to make the impossible possible. So take advantage of the unique benefits we offer you with our quality and manufacturing strategy.