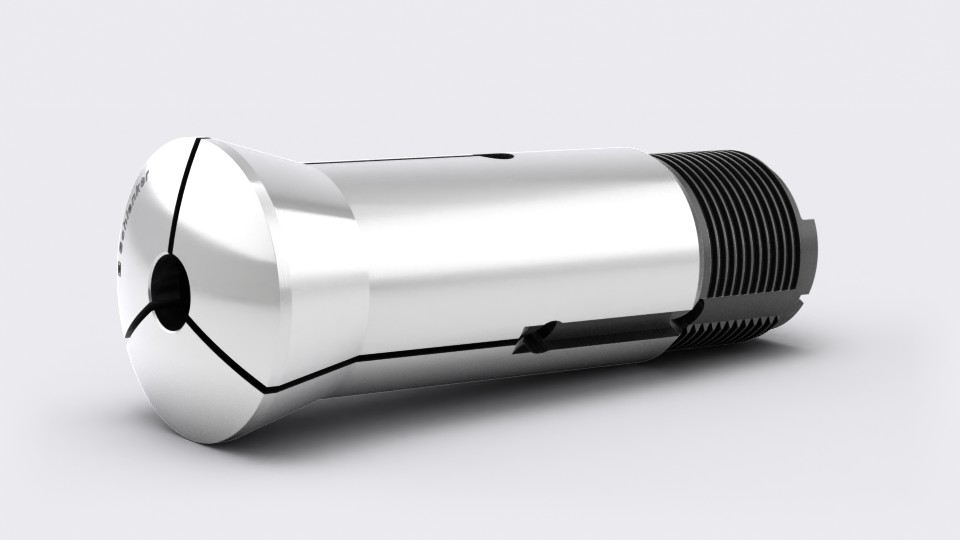

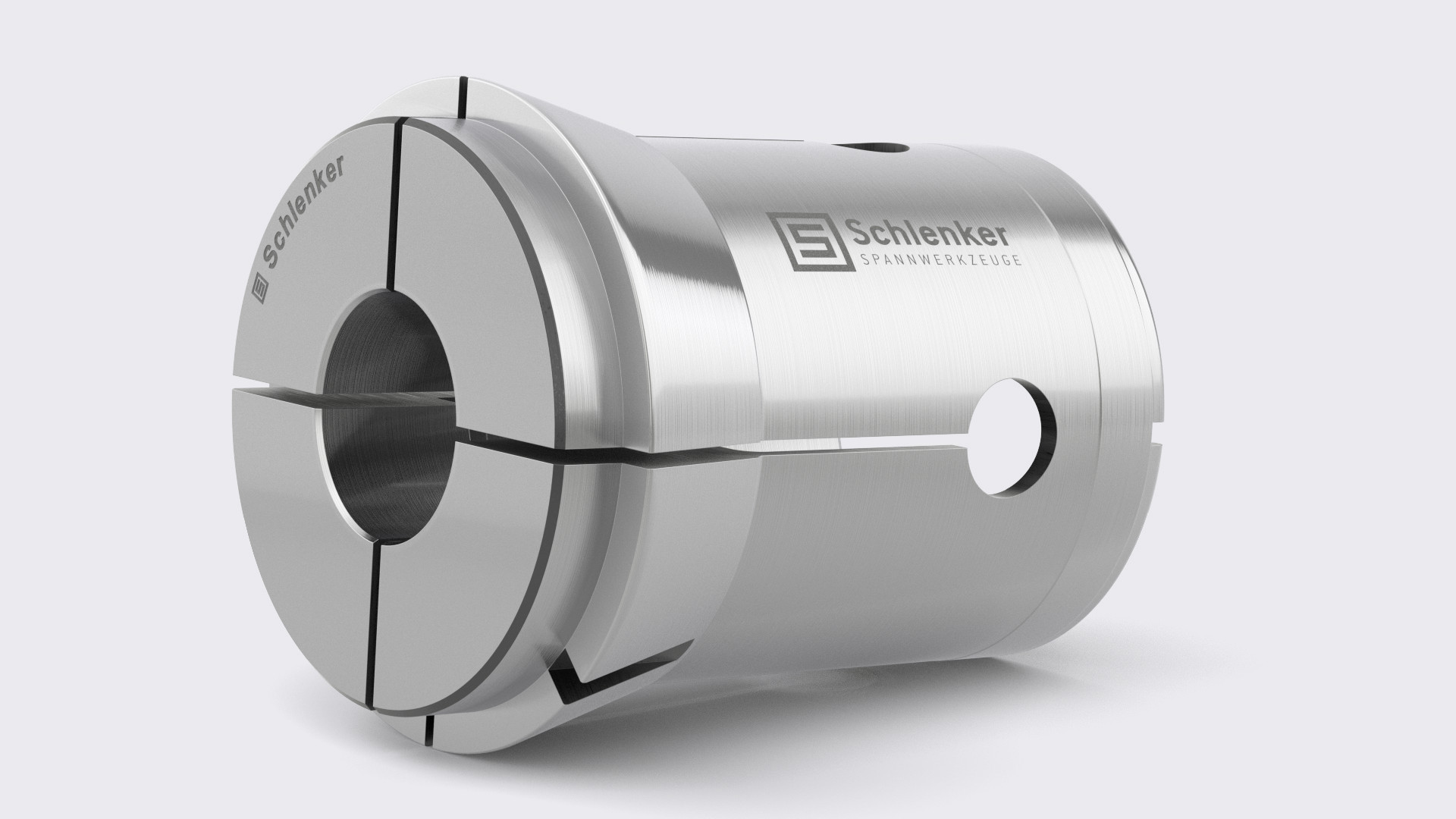

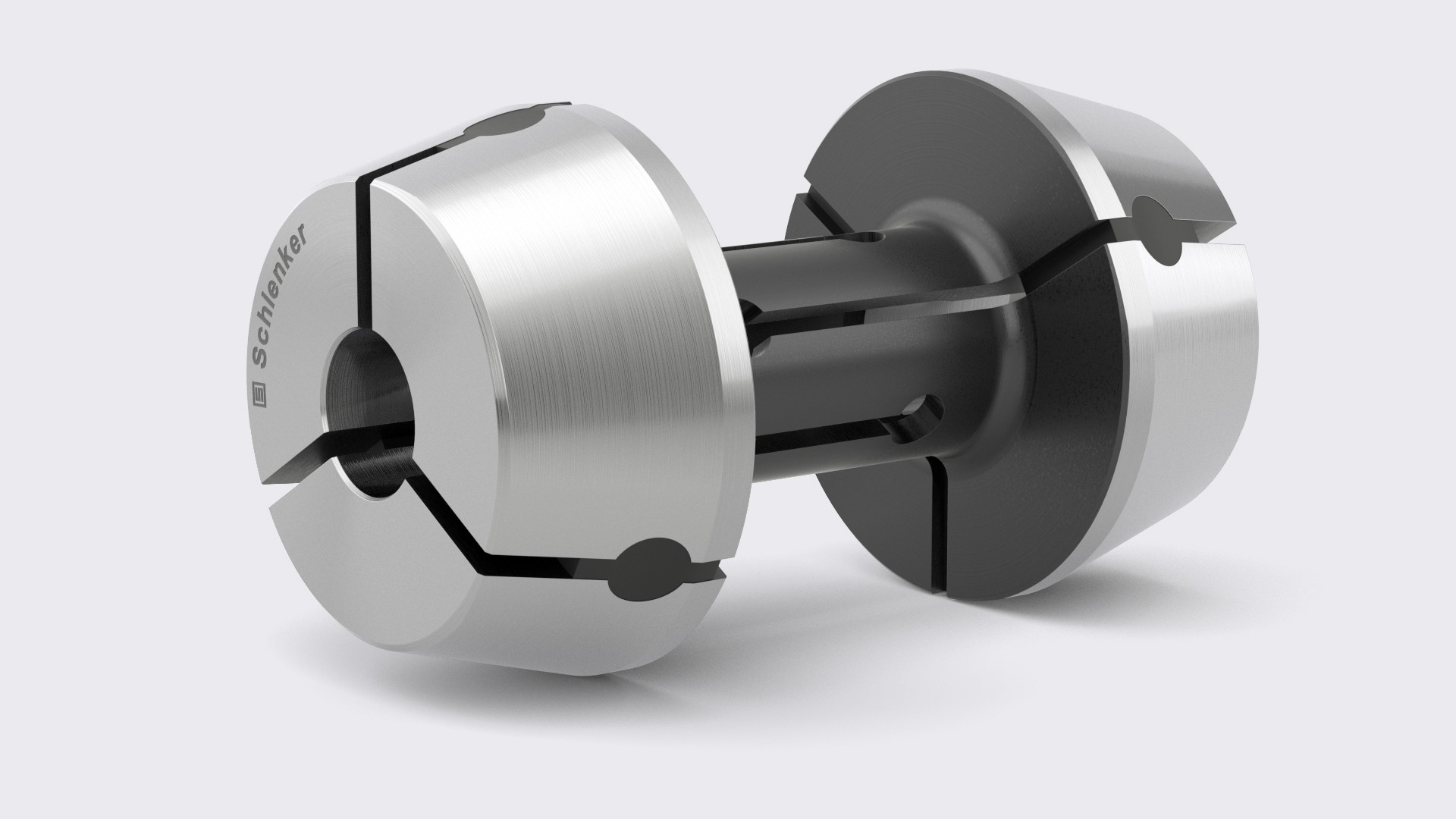

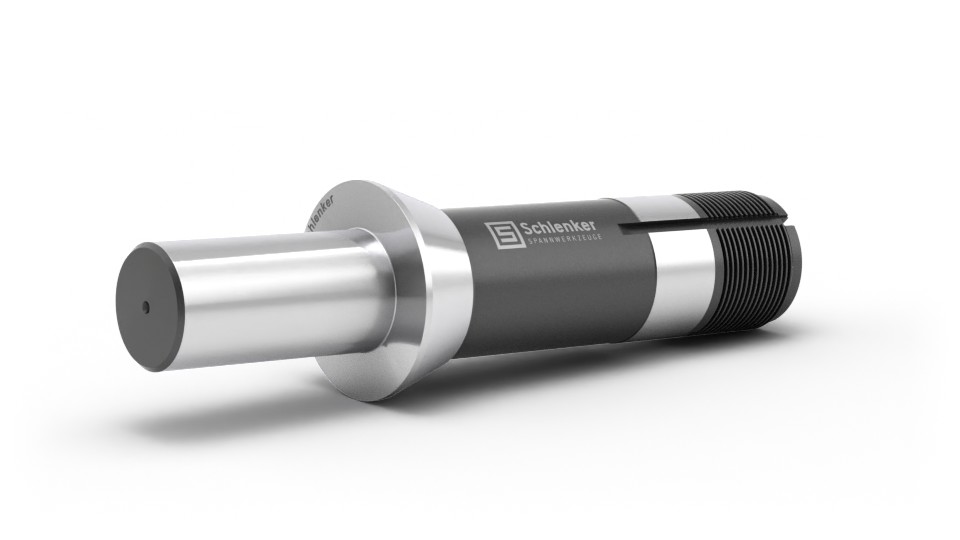

COLLETS

Collets are used in manuel and CNC lathes for workpiece clamping. They are installed directly in the spindle or in the collet chuck.

Our collets are used by well-known machine manufacturers, such as CITIZEN, DMG MORI, GILDEMEISTER, HANWHA, INDEX/TRAUB, MAIER, STAR, SCHÜTTE, TORNOS und TSUGAMI.