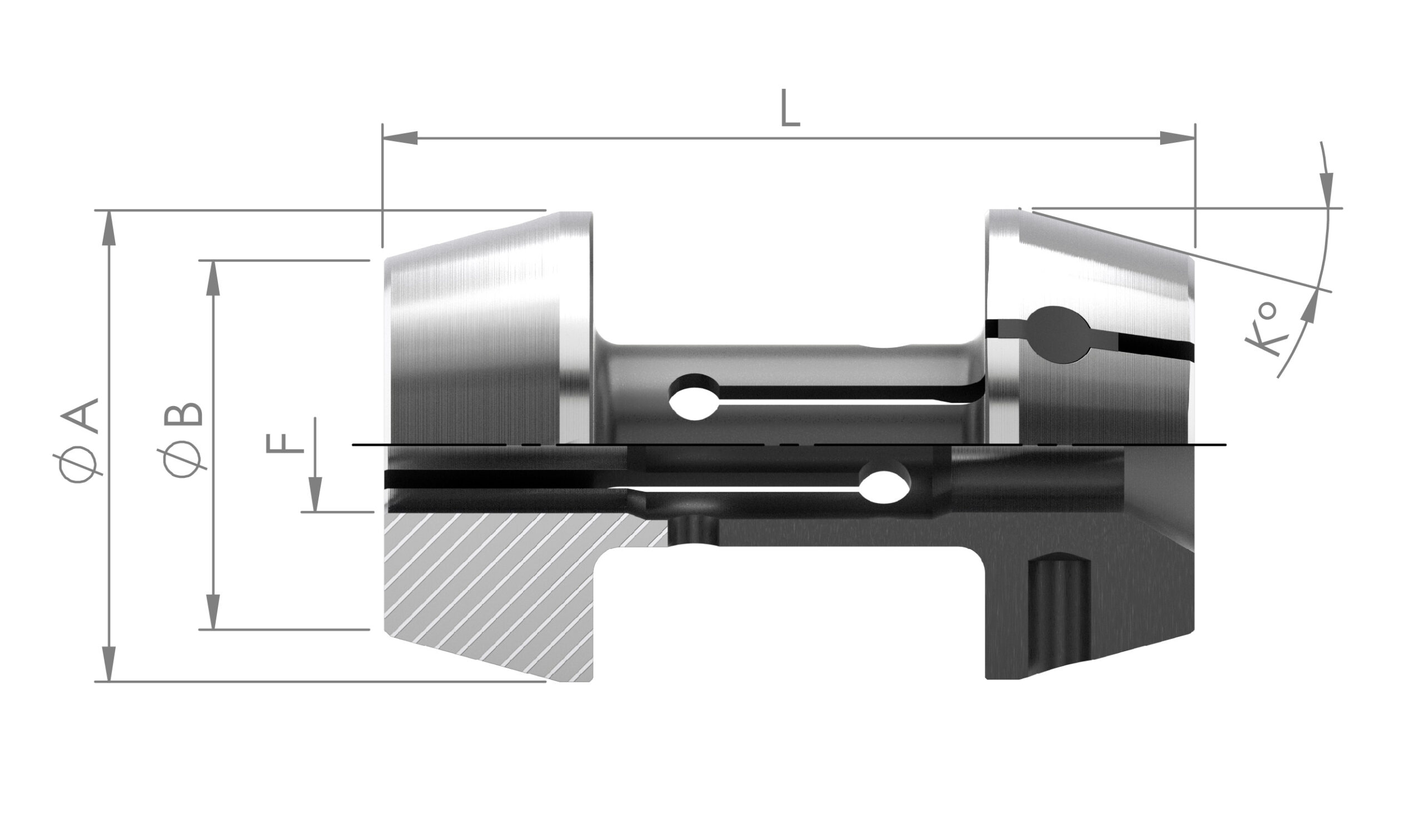

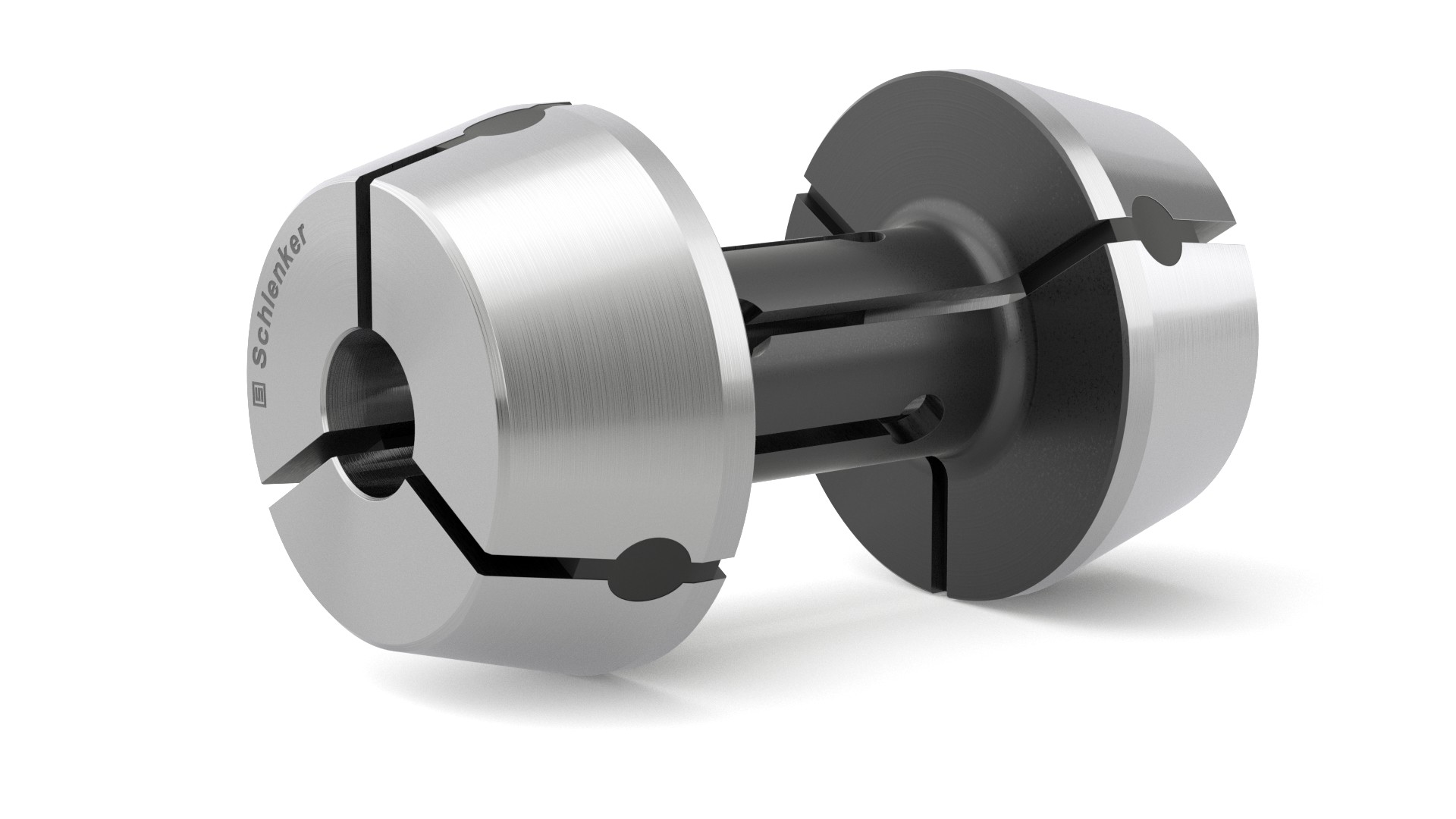

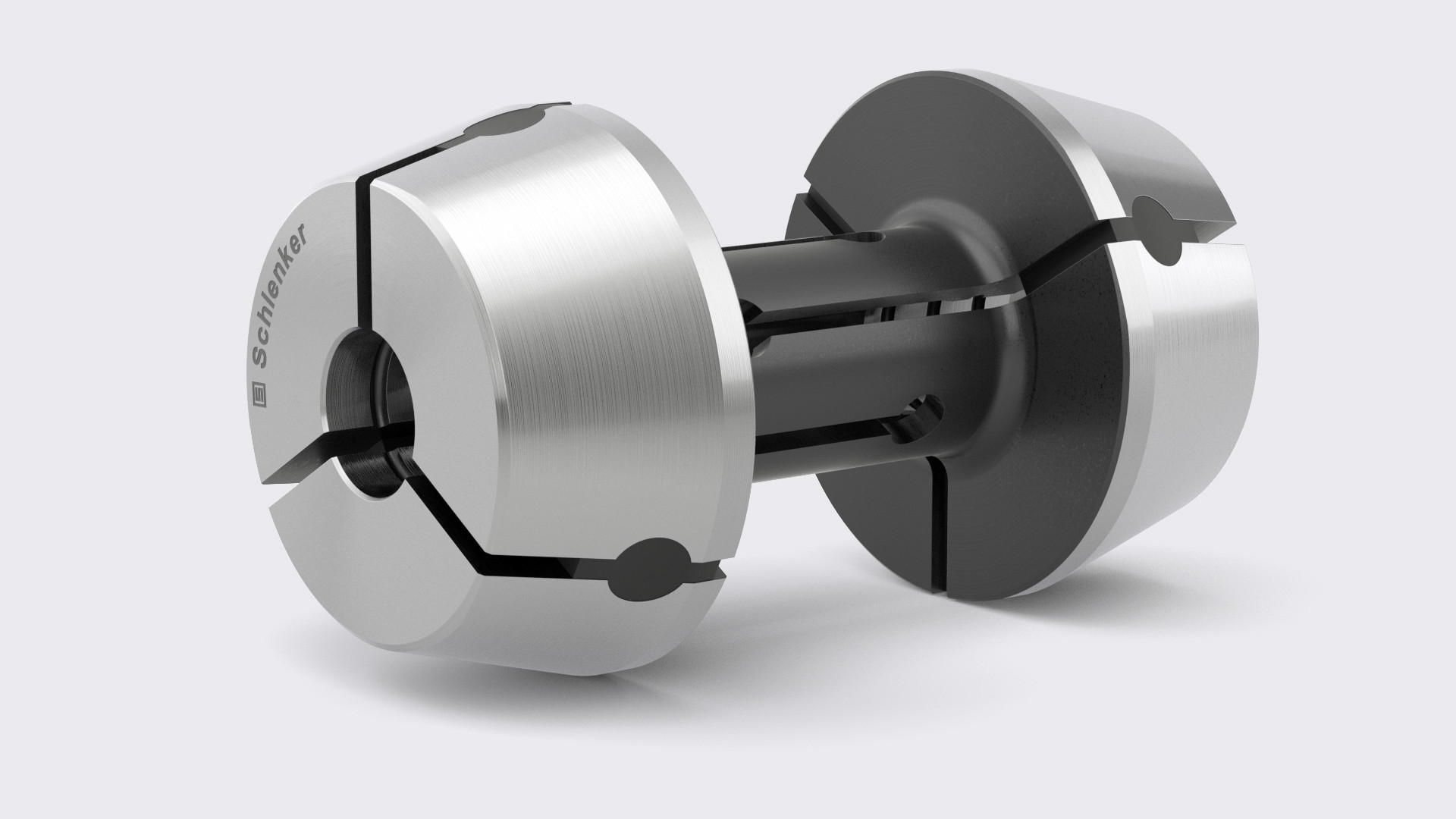

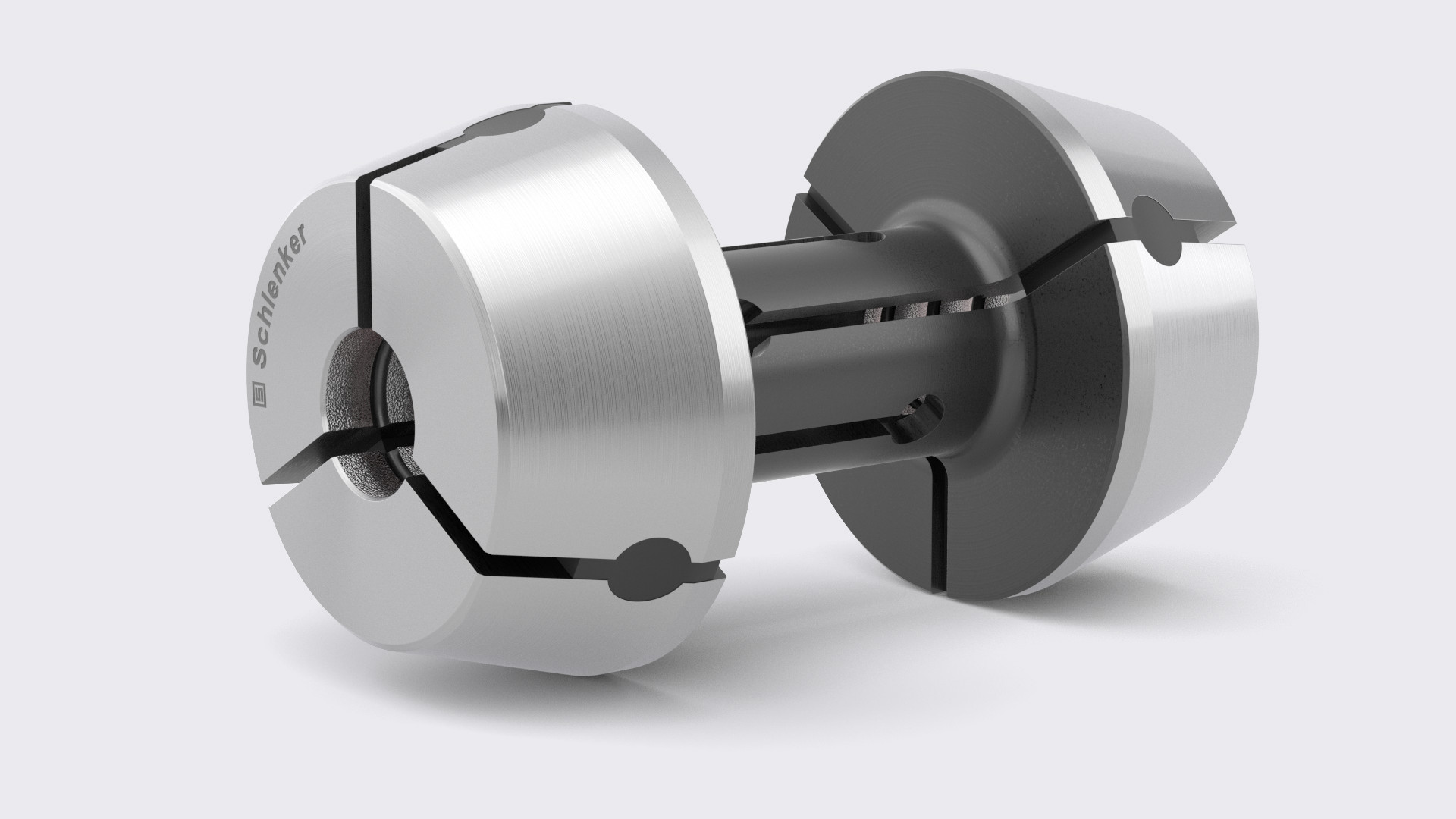

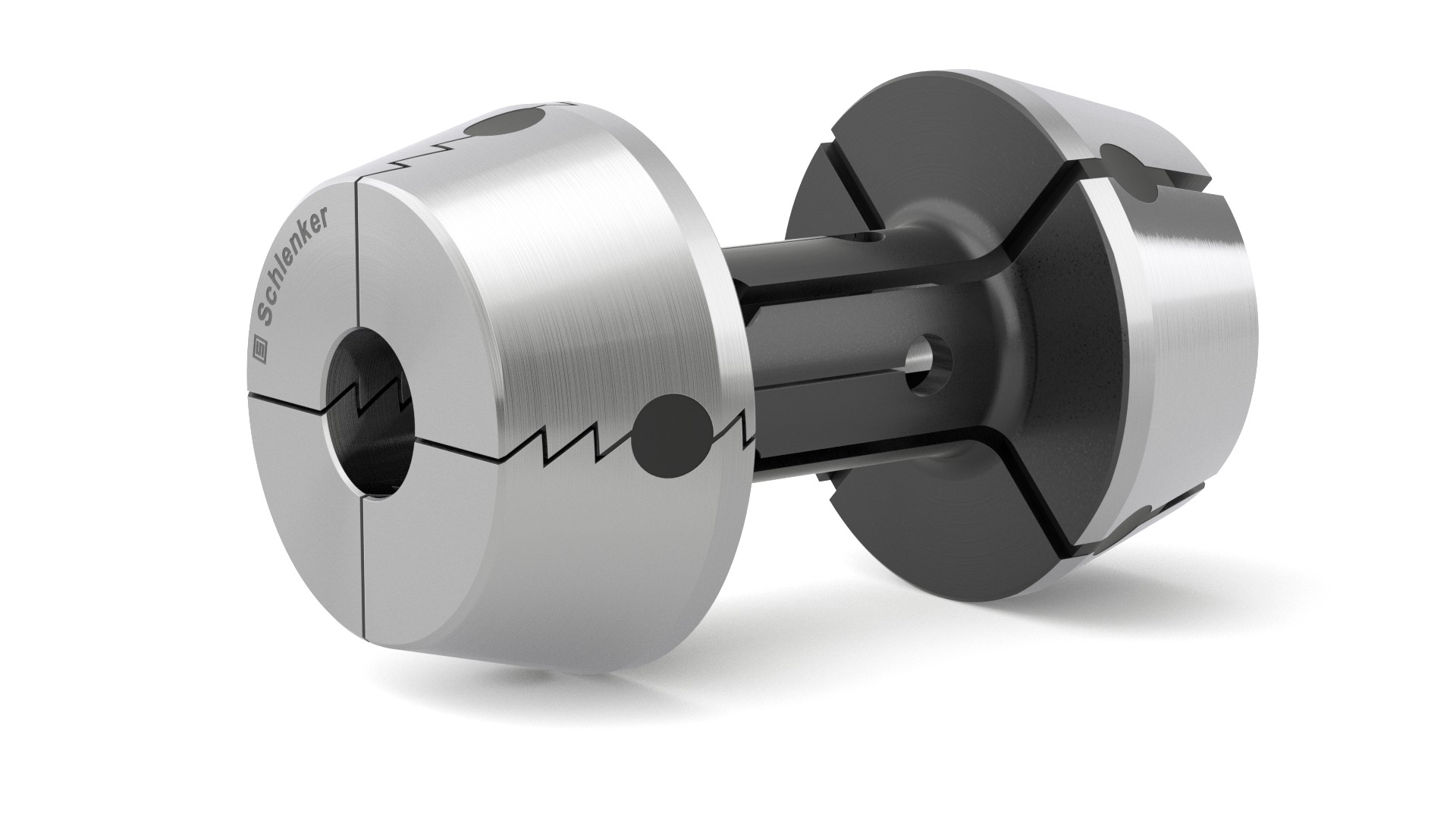

S-SLOT

- High and constant clamping force

- Clamping with virtually no clamping marks

- Alternatively usable for profile material (corner clamping)

- Prevents the entry of machining chips, as the collet closes almost completely

- Easy to clean after use

Click on details to compare this product with the standard version

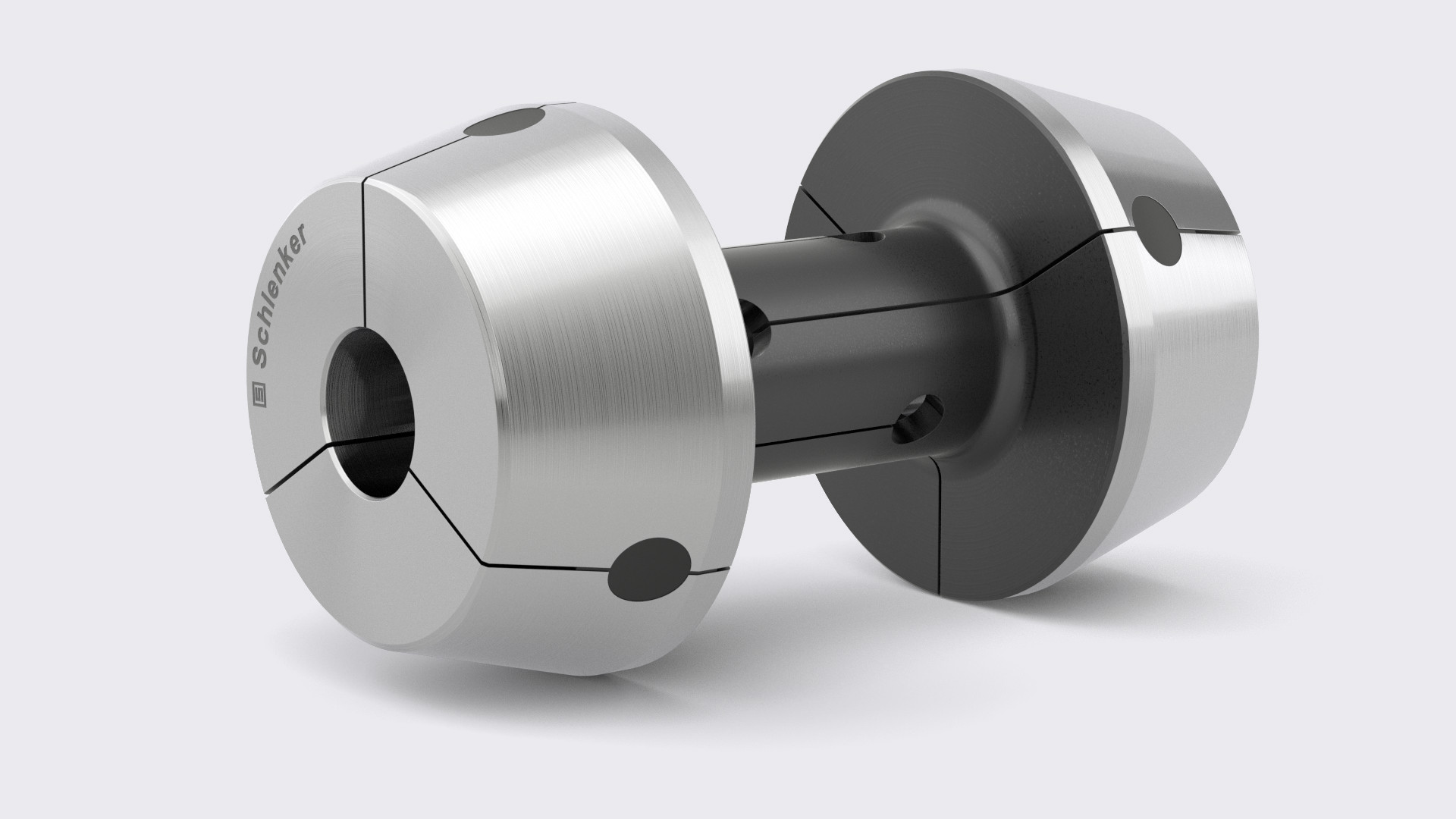

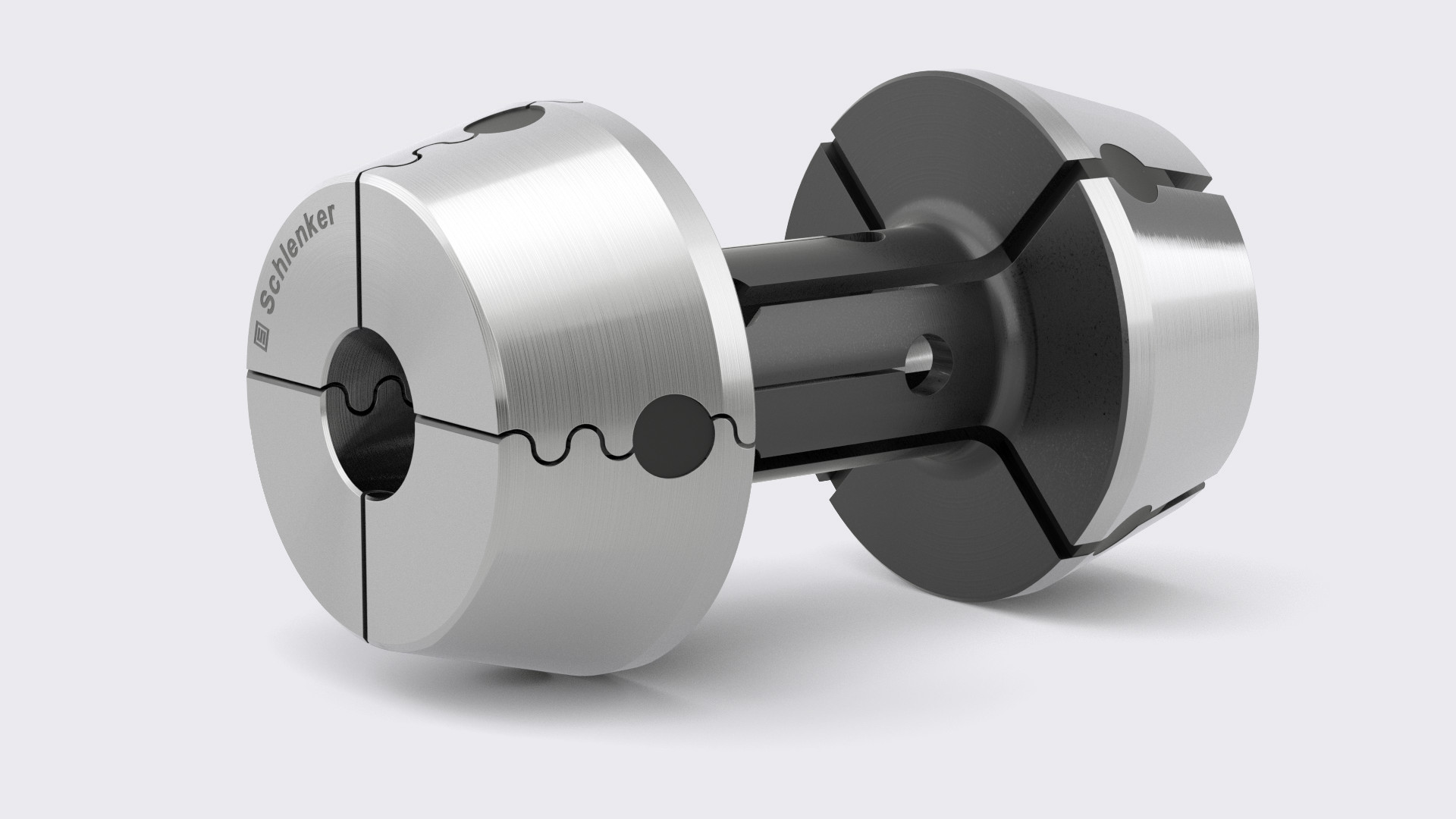

W-SLOT

- High and constant clamping force

- Clamping with virtually no clamping marks

- Alternatively usable for profile material (corner clamping)

- Prevents the entry of machining chips, as the collet closes almost completely

- Easy to clean after use

Click on details to compare this product with the standard version

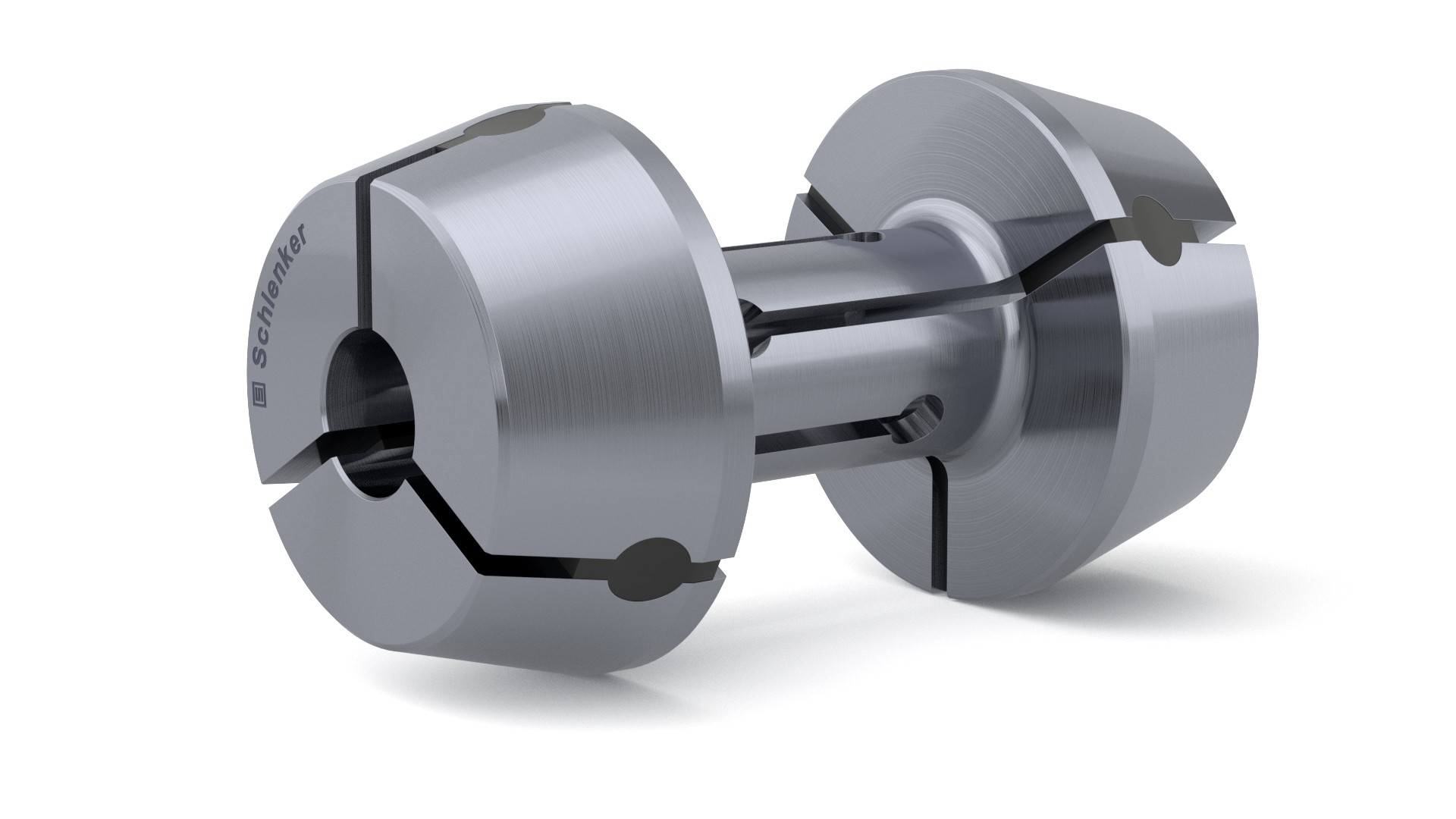

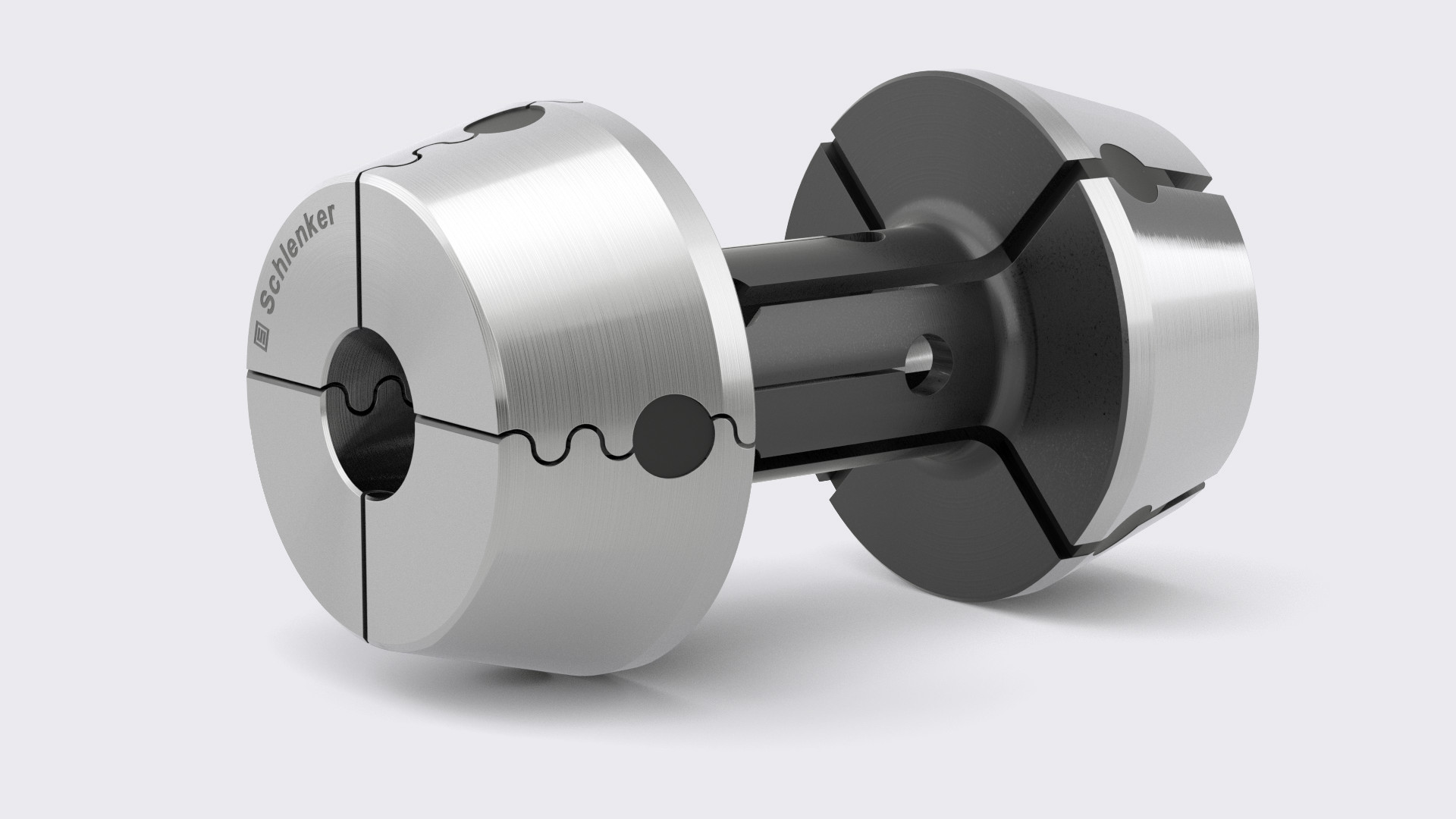

Z-SLOT

- High and constant clamping force

- Clamping with virtually no clamping marks

- Alternatively usable for profile material (corner clamping)

- Prevents the entry of machining chips, as the collet closes almost completely

- Easy to clean after use

Click on details to compare this product with the standard version