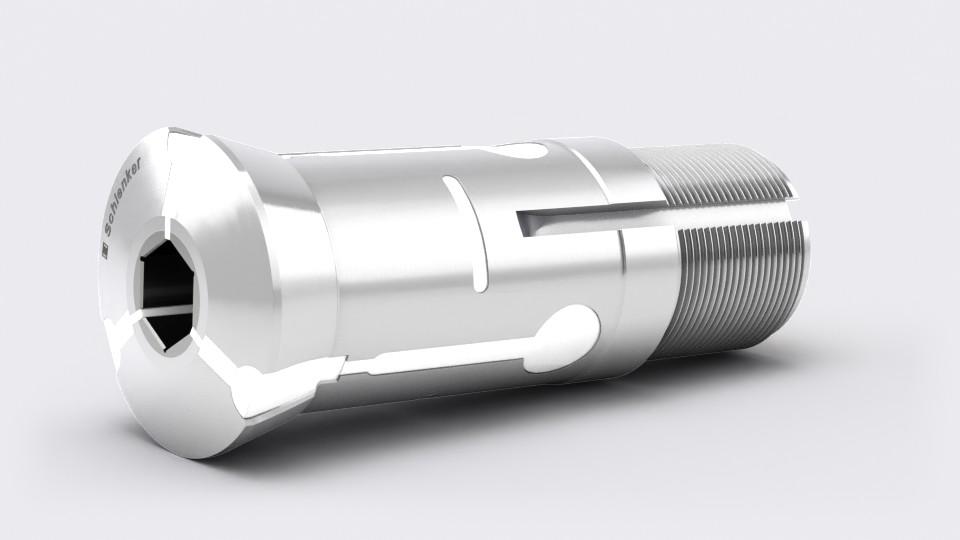

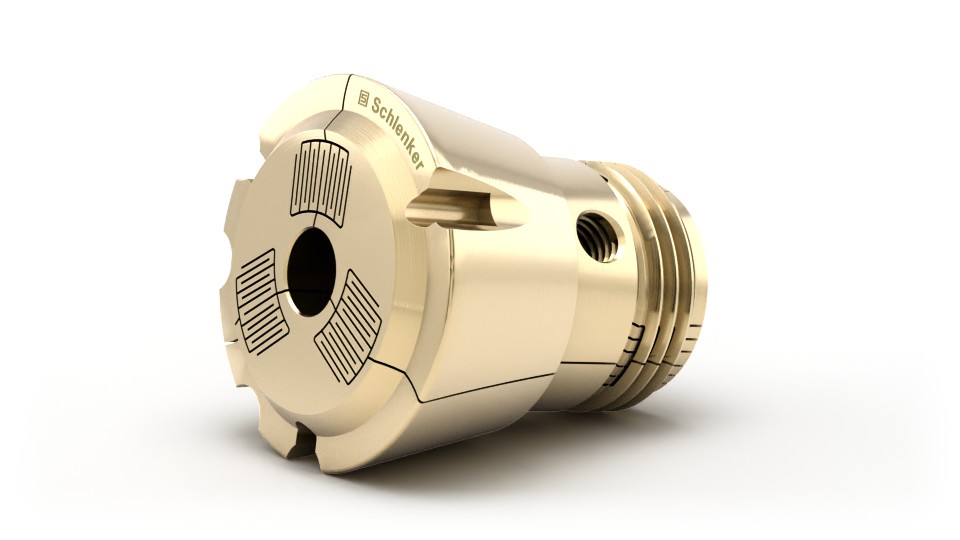

GUIDE BUSHES

The high-precision guide bushes are used in sliding headstock automatic lathes to stabilize the bar stock during machining.

Our guide bushes are used by well-known machine manufacturers, such as CITIZEN, DMG MORI, DOOSAN, GILDEMEISTER, HANWHA, INDEX/TRAUB, MAIER, MANURHIN, STAR, TORNOS and TSUGAMI.