DEAD LENGTH COLLET ALIGNMENT MANDRELS VERSION

Our alignment mandrels for collets are used in all common machines. They are characterized above all by their precision and durability.

Test our dead length collet alignment pins now, you will be convinced.

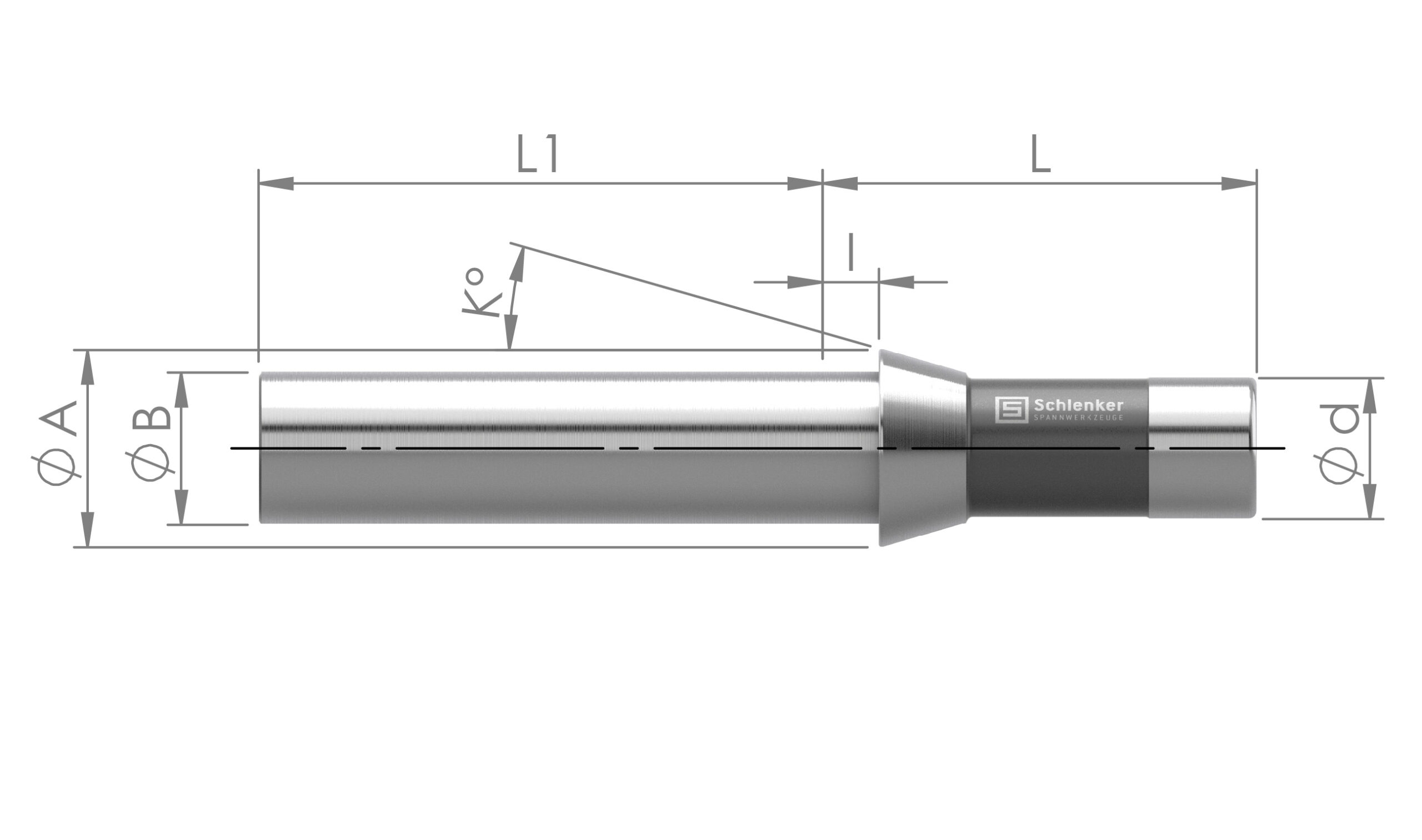

DEAD LENGTH COLLET ALIGNMENT MANDRELS

- Available for all dead length collet types from our range

Click on the product image to get 360° view

| d | Shaft-Ø |

| A | Head-Ø |

| B | Nose-Ø |

| L1 | Length L1 |

| L | Total length |

| K | Taper angle |

| G | Thread |

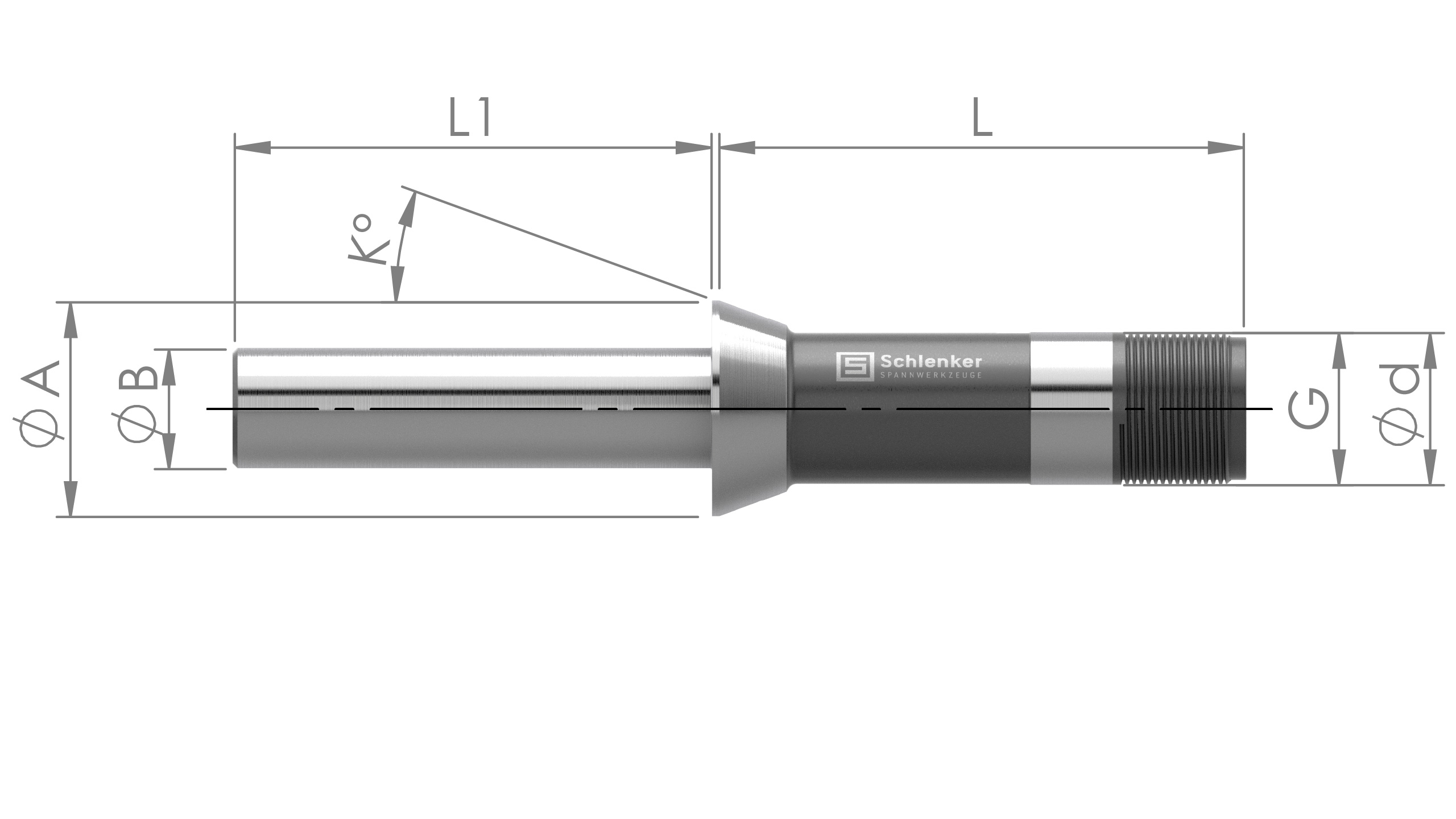

DRAW-IN COLLET ALIGNMENT MANDRELS TYPE

Our alignment mandrels for draw-in collets are used in all common machines. They are characterized above all by their precision and durability.

Test our draw-in collet alignment pins now, you will be convinced.

DRAW-IN ALIGNMENT MANDRELS

- Available for all draw-in collet types from our range

Click on the product image to get 360° view

| A | Outside diameter |

| G1 | Thread |

| G2 | Thread |

| L | Total length |

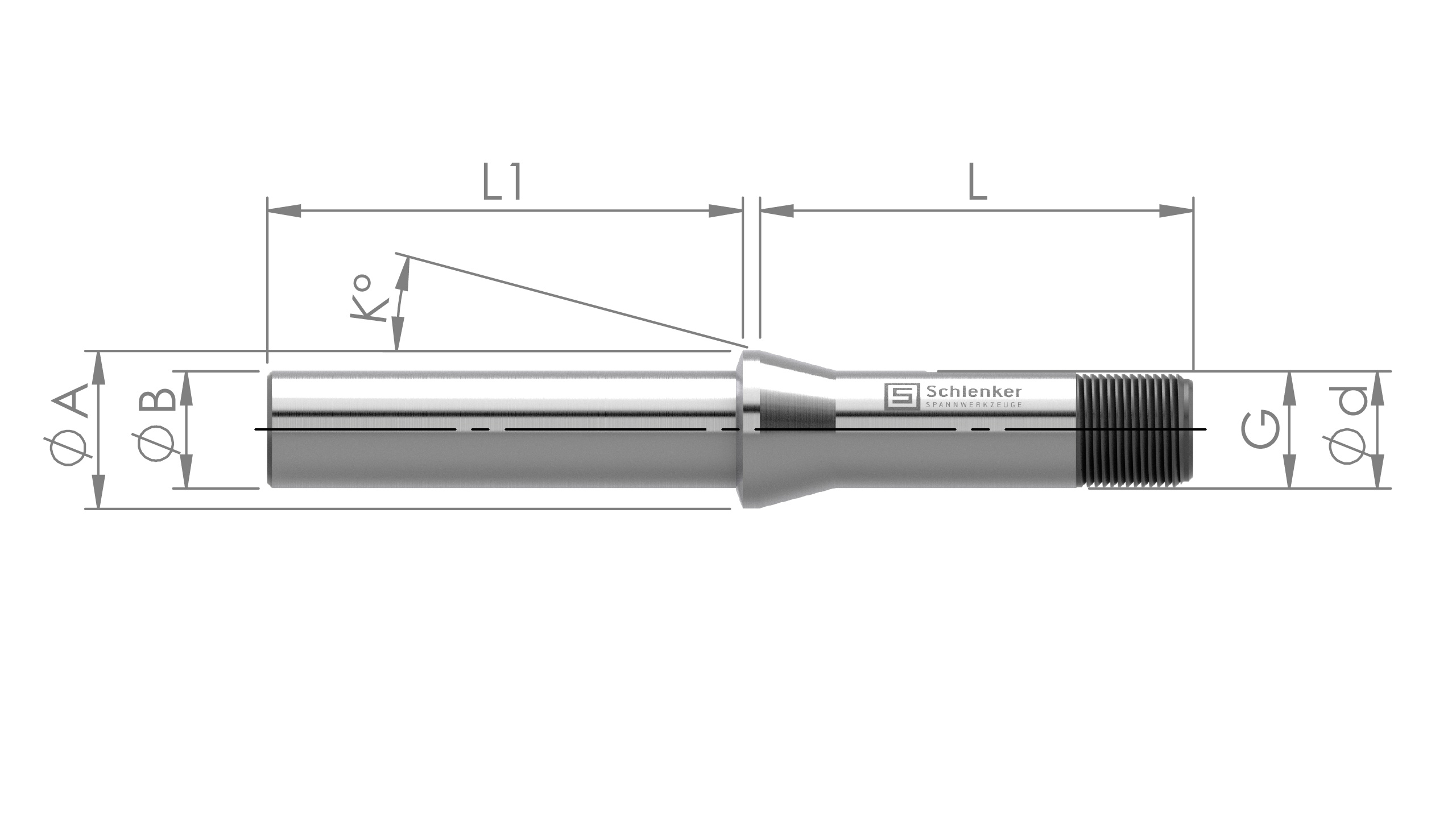

DRAW-IN COLLET SW&B ALIGNMENT MANDRELS VERSION

Our alignment mandrels for draw-in collets SW&B are used in all common machines. They are characterized above all by their precision and durability.

Test our draw-in collet SW&B alignment pins now, you will be convinced.

DRAW-IN COLLET SW&B ALIGNMENT MANDRELS

- Available for all draw-in SW&B collet types from our range

Click on the product image to get 360° view

| A | Outside diameter |

| G1 | Thread |

| G2 | Thread |

| L | Total length |

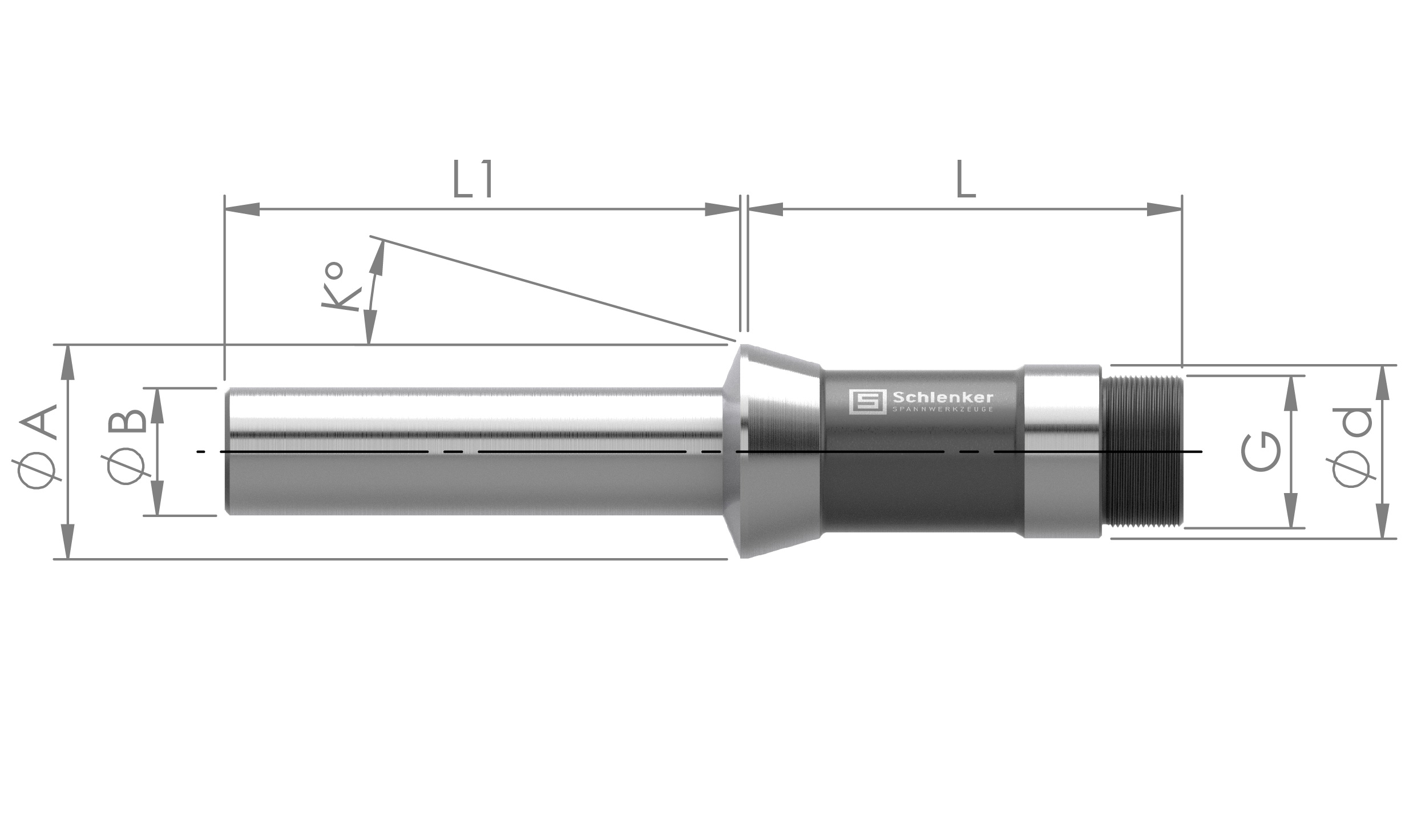

MULTI-SPINDLE ALIGNMENT MANDRELS VERSION

Our alignment mandrels for multi-spindle collets are used in all common machines. They are characterized above all by their precision and durability.

Test our multi-spindle collet alignment pins now, you will be convinced.

MULTI-SPINDLE COLLET ALIGNMENT MANDRELS

- Available for all multi-spindle collet types from our range

Click on the product image to get 360° view